Brand: ATORN

Surface: ULTRA H

Length: 104 mm

Art.-no. 16855620

Manufacturer article no. 10617349

EAN 4050293411263

Application

HPC end mill for high-strength materials up to 1600 N/mm² and hardened steel up to 55 HRC – optimal application in trochoidal milling and in edge, corner and groove machining.

Execution

- Solid carbide ultra-fine grain

- ULTRA H high-performance coating

- Centre cutting

- Uneven twist angle: 35°/38°

- Unequal cutting edge pitch

- Optimised cutting edge design

- With clearance

- Cutting edge with edge preparation

Advantage

- Increased material removal rate

- High process reliability owing to robust cutting edges

- Very good surface quality

- Reduces vibrations

- Ideal for static and dynamic trochoidal milling

| |

Brand | ATORN |

Main EAN Code | 4050293411263 |

Manufacturer Part Number | 10617349 |

Cutting material | SC |

Surface | ULTRA H |

Type | H |

Number of cutting edges (Z) | 4 PCS |

Twist angle | 35° |

Tool holding device | HB parallel shank |

Construction length | Normal |

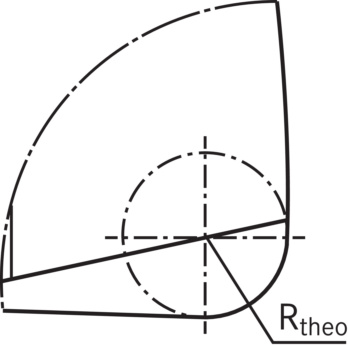

Cutting edge diameter | 20 mm |

Cutting edge length | 44 mm |

Clearance length | 54 mm |

Length | 104 mm |

Clearance diameter | 19 mm |

Shank diameter | 20 mm |

fz hard 52 HRC | 0.08 mm |

Gross Weight | 0.390 kg |

| Material groups for cutting values | Description regarding DIN | Strength Class [N/mm²] | Material No. | Vc [m/min] | fz [mm/T] at diameter | Suitability |

|---|---|---|---|---|---|---|

| 1.00 Steels | ||||||

| 1.01 Free machining steel | 9 S 20 | < 900 | 1.0711 | - | ⚪ | |

| 1.02 Structural steel | ST 37-2 | <500 | 1.0037 | - | ⚪ | |

| 1.03 Structural steel | ST 60-2 | > 500 | 1.7735 | - | ⚪ | |

| 1.04 Heat-treated steel | 42 CrMo 4 | <1000 | 1.7225 | 120-140 | 0.1 | ⚫ |

| 1.05 Cast iron | GS-45 | <1000 | 1.0446 | 120-140 | 0.1 | ⚫ |

| 1.06 Case-hardened steel | 16 MnCr 5 | <1200 | 1.7131 | 120-140 | 0.1 | ⚫ |

| 1.07 Ferritic/martensitic stainless steel | X 10 Cr 13 | <1100 | 1.4006 | 120-140 | 0.1 | |

| 1.08 Heat-treated steel | 43 CrMo 4 | >1000 | 1.3563 | 120-140 | 0.1 | ⚫ |

| 1.09 Nitriding steel | 31 CrMoV 9 | <1300 | 1.8519 | 100-120 | 0.1 | ⚫ |

| 1.10 Tool steel | X 38 CrMoV 5 1 | <1300 | 1.2343 | 100-120 | 0.1 | ⚫ |

| 4.00 Cast metal | ||||||

| 4.01 Grey cast iron | GG10 | <260 HB | 0.6010 | 180-220 | 0.14 | ⚪ |

| 4.02 Spheroidal graphite iron | GGG 40 | <310 HB | 0.7040 | 150-180 | 0.12 | ⚪ |

| 4.03 Ductile iron | GTW-55 | <280 HB | 0.8055 | 120-150 | 0.12 | ⚪ |

| 6.00 Hard materials | ||||||

| 6.01 Hardened steel -55 HRC | x40CrMoV5-1 | -55HRC | 0.9620 | 80-100 | 0.07 | ⚫ |

| 6.02 Hardened steel -65 HRC | 90MnCrV8 | <65HRC | - | |||