Brand: ATORN

Surface: ULTRA

Length: 120 mm

Art.-no. 11542125

Manufacturer article no. 11201284

EAN 4066107036171

Application

For producing 45° chamfers and for deburring up to 1,300 N/mm²

Execution

- Defined cutting edge rounding

- 3-5 teeth

- High-performance ULTRA coating for universal application

- Extra-long version for hard-to-reach areas

Notes

Shank variant HA up to dia. 4 mm

| |

Brand | ATORN |

EAN | 4066107036171 |

Manufacturer Part Number | 11201284 |

Cutting edge diameter | 12 mm |

Werkstückkante | 45 Grad |

Chamfer angle | 90 Degree |

Type | N |

Number of cutting edges (Z) | 5 PCS |

Insert diameter min. | 1.2 mm |

Surface | ULTRA |

Shank diameter | 12 mm |

Tool holding device | HB parallel shank |

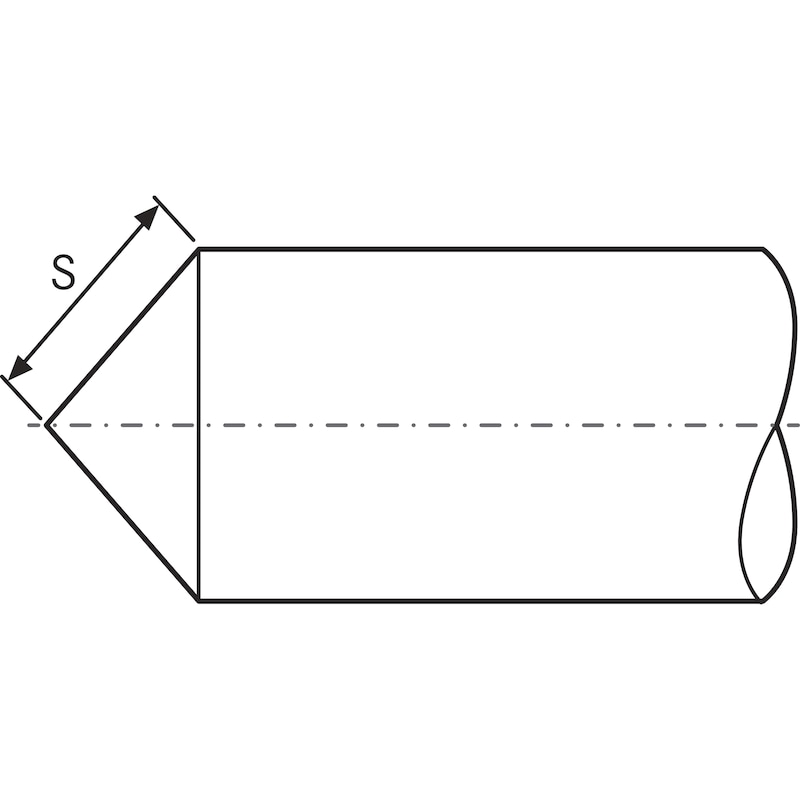

Cutting edge length (S) | 7.6 mm |

Length | 120 mm |

Harmonized System Code | 82077010 |

Gross Weight | 0.209 kg |

SC chamfer mill 90°

ATORNFor example:

1x gloves: 1 pair (2 pieces)

1x bit set: 1 set (10 pieces)

1x screw: package (50 pieces)

First 5 digits = material no . / Product no . + last 3 digits = dimensions / diameter / article no.

For example, solid carbide end mills 3x5x50mm first 5 digits 16851 + last 3 points 050

article no.: 16851050

The displayed price is always in line with the displayed packaging, if the PU is 250 the price for 250 units, if the PU is 300 the price for 300 units.

Price with price key representation (PSL):

The price always applies to a quantity ruled through the price key:

Price for 1 unit

Price for 100 units

Price for 1000 units