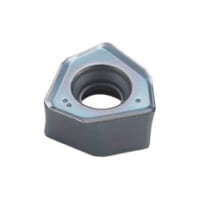

Brand: ATORN

Surface: ULTRA

Length: 63 mm

Art.-no. 16856036

Manufacturer article no. 10911628

EAN 4050293098761

Application

HPC torus milling cutter with uneven pitch for universal rough machining and smoothing.

Execution

- Solid carbide ultra-fine grain

- Straight shank in accordance with DIN 6535 HB

- ULTRA-coated

- Centre cutting

- Unequal cutting pitch

Brand | ATORN |

EAN | 4050293098761 |

Manufacturer Part Number | 10911628 |

Cutting material | SC |

Surface | ULTRA |

Type | N |

Number of cutting edges (Z) | 4 PCS |

Twist angle | 30° |

Tool holding device | HB parallel shank |

Construction length | Normal |

Cutting edge diameter | 8 mm |

Cutting edge length | 21 mm |

Clearance length | 25 mm |

Length | 63 mm |

Clearance diameter | 7.4 mm |

Shank diameter | 8 mm |

Edge radius | 1 mm |

fz steel 1000 | 0.05 mm |

Harmonized System Code | 82077010 |

Gross Weight | 0.020 kg |