Brand: ATORN

Surface: TiAlN

Length: 39 mm

Art.-no. 13496852

Manufacturer article no. 11947965

EAN 4050293658828

| |

Brand | ATORN |

Main EAN Code | 4050293658828 |

Manufacturer Part Number | 11947965 |

Cutting material | SC |

Surface | TiAlN |

Hole type | Clearance/blind hole ≤ 4xD |

Coolant supply | External |

Tool holding device | HA parallel shank |

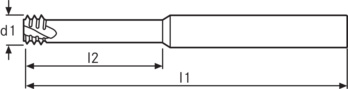

Cutting edge diameter (d1) | 2.4 mm |

Pitch | 0.5 mm |

Suitable for metric threads from | M3 |

Length (l1) | 39 mm |

Effective length of thread milling (l2) | 12.5 mm |

Shank diameter | 3 mm |

Number of cutting edges | 3 PCS |

f steel 1000 | 0.05 mm/r |

Harmonized System Code | 82077031 |

Product Group | 132 |

Gross Weight | 0.006 kg |