ORION subland stepped drill bit type N, HSS M8 9 mm HA

Brand: ORION

Surface: Vaporised

Length: 125 mm

DIN: 8378

Art.-no. 11106008

Manufacturer article no. 11106008

EAN 4039247026463

Application

For thread core holes in accordance with DIN 336 and 90° free countersink equivalent to through holes in accordance with DIN EN 20273. Countersink and thread core holes are manufactured in one machining step.

Execution

- Drill and countersink step with independent chip grooves and drill heels; regrinding does not affect the profile

Advantage

- precise alignment of drill diameter and countersink diameter, lower process costs

- universal use, therefore tool costs are reduced to a minimum and user flexibility is increased

| |

Brand | ORION |

Main EAN Code | 4039247026463 |

Manufacturer Part Number | 11106008 |

Cutting material | HSS |

Surface | Vaporised |

Type | N |

Angle of the tip | 118 Degree |

Coolant supply | External |

Tool holding device | HA parallel shank |

Suitable for screw thread | M8 |

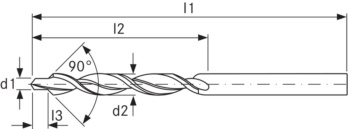

Pilot hole diameter (d1) | 6.8 mm |

Spot-facer diameter (d2) | 9 mm |

Pilot hole length (l3) | 21 mm |

Chip flute length (l2) | 81 mm |

Length (l1) | 125 mm |

Shank diameter | 9 mm |

f steel 700 | 0.1 mm/r |

DIN | 8378 |

Harmonized System Code | 82075060 |

Gross Weight | 0.045 kg |